As we all know,

polyacrylamide can be widely used in many industries, many of which need to dissolve the polyacrylamide, so that it becomes a solution for use, but in the proportioning of the solution, in order to ensure the use of efficiency, need to be in accordance with the provisions of the proportioning method and the precautions for the operation, so as to meet the needs of various industries.

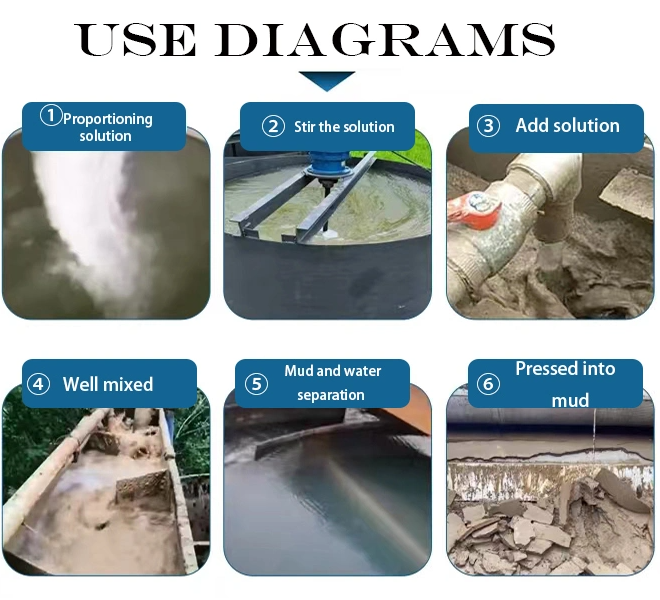

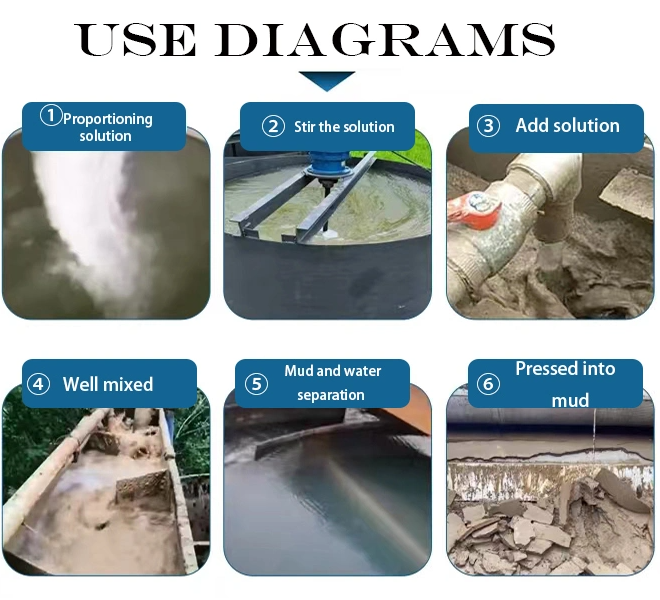

1. Solid particles should be dissolved in 1‰-5‰ concentration of aqueous solution before dissolving for use, so as to play a rapid role in the process of dosing, using a step-by-step method of dosing, the water is slowly put into the water, so that it is evenly dispersed and dissolved in the water.

2. The solution is usually added to 0.5‰-1‰ aqueous solution, but in the case of high concentration and viscosity of suspension, it is recommended to further dilute to 0.1‰ to facilitate mixing and give full play to its role.

3. The molecular weight of the cation is smaller than that of the anion, so the viscosity of the cation is also weaker than that of the anion therefore, the concentration standard of the cation and the nonion is slightly higher than that of the anion (according to the situation, it can also be adjusted according to the concentration of the water if the concentration is lower, it can be increased appropriately) the concentration of the recommendation is 5 ‰ – 1 ‰.

Second, polyacrylamide solution preparation precautions:

1, polyacrylamide aqueous solution should be prepared in enamel, galvanised, aluminium or plastic drums, shall not be prepared and stored in iron containers.

2, the dissolution should be careful to add the product evenly and slowly into the solvent, and take stirring and heating measures to avoid solid deposition, prepare the solution at the appropriate temperature, avoid excessive mechanical shear for a long time suggests that the stirrer speed of 60-200rpm, otherwise it will cause polymer degradation, affecting the use of the effect.

3, polyacrylamide aqueous solution should be prepared on site when the solution is placed for a longer period of time, its performance will gradually decrease with the changes in water quality.

4、After adding flocculant aqueous solution in suspension, if it is stirred violently for a long time, the floc formed will be destroyed.

Third, the scope of application of polyacrylamide: (PAM applicability)

1, used as retention aid and enhancer in the papermaking process.

2、As a coagulant aid, flocculant and sludge dewatering agent in water treatment.

3、It is used as precipitant and oil repellent in oil drilling.

4、It is also widely used in the fields of thickening, stabilising colloid, drag reduction, bonding, film formation, biomedical materials and so on.

In short, in order to ensure the use of polyacrylamide efficiency, we should be in accordance with the provisions of the proportioning method, but also need to have an understanding of the preparation of the notes, so as to avoid the use of inappropriate methods, proportioning substances are incompatible with the performance and quality of polyacrylamide, not only affecting the use of, but also cause waste.

The main products of flocculant manufacturer Xinhuan Water Treatment are:

White polyaluminium chloride (food grade),

drinking grade polyaluminium chloride,

industrial grade polyaluminium chloride,

anionic polyacrylamide,

cationic polyacrylamide, nonionic polyacrylamide, petroleum recycling polyacrylamide, oil recovery polyacrylamide, polyacrylamide, polymer flocculant polymer flocculation coagulant, polymeric ferrous sulphate, polymerized iron and aluminium chloride, and other water treatment chemicals. Welcome customers to write to us to negotiate business! Tel/WhatsApp:86 15936201203 Email:maggie@xhwtm.com Contact:Maggie

The main products of flocculant manufacturer Xinhuan Water Treatment are:

White polyaluminium chloride (food grade), drinking grade polyaluminium chloride, industrial grade polyaluminium chloride, anionic polyacrylamide, cationic polyacrylamide, nonionic polyacrylamide, petroleum recycling polyacrylamide, oil recovery polyacrylamide, polyacrylamide, polymer flocculant polymer flocculation coagulant, polymeric ferrous sulphate, polymerized iron and aluminium chloride, and other water treatment chemicals. Welcome customers to write to us to negotiate business! Tel/WhatsApp:86 15936201203 Email:maggie@xhwtm.com Contact:Maggie

The main products of flocculant manufacturer Xinhuan Water Treatment are:

White polyaluminium chloride (food grade), drinking grade polyaluminium chloride, industrial grade polyaluminium chloride, anionic polyacrylamide, cationic polyacrylamide, nonionic polyacrylamide, petroleum recycling polyacrylamide, oil recovery polyacrylamide, polyacrylamide, polymer flocculant polymer flocculation coagulant, polymeric ferrous sulphate, polymerized iron and aluminium chloride, and other water treatment chemicals. Welcome customers to write to us to negotiate business! Tel/WhatsApp:86 15936201203 Email:maggie@xhwtm.com Contact:Maggie