Coal washing is an important process in coal processing to remove impurities and ash from coal and improve coal quality through sorting, flotation and re-election. In the coal washing process, coal slurry is a common by-product with high water content, which needs to be dewatered. However, in actual production, the problem of coal slurry not being pressed dry often occurs, which affects the dewatering efficiency and product quality.

Reasons for coal slurry not being pressed dry

Nature of coal slurry

Coal slurry is a kind of material with fine particles and high water content, whose nature directly affects its dewatering performance. Generally speaking, the more complicated the nature of coal slurry is, the more difficult it is to dewater. For example, coal slurry containing clay minerals is easy to produce cementation phenomenon and difficult to dewater; coal slurry containing stable foam is difficult to separate.

Equipment Status

Commonly used equipment for coal slurry dewatering include filter presses, centrifuges, etc. The state of these equipments directly affects the dewatering effect of coal slurry. For example, problems such as broken filter cloth and poor sealing of the filter press will lead to incomplete dewatering of coal slurry; the rotational speed of the centrifuge and the cleaning state of the drum shell will also affect the dewatering effect of coal slurry.

Operation problems

In the process of coal slurry dewatering, operation problems can also easily cause the coal slurry not to be pressed dry. For example, excessive stirring of coal slurry will increase its viscosity and make it difficult to dewater; excessive dosing will lead to too high concentration of additives in coal slurry and affect the dewatering effect.

Solution

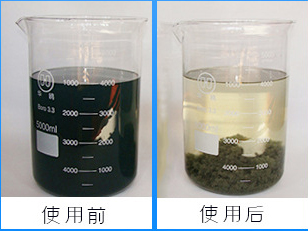

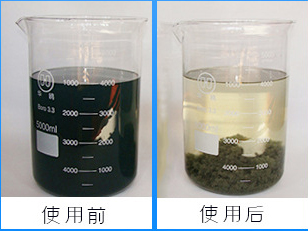

Optimize the nature of coal slurry

The dewatering effect of coal slurry can be improved by optimizing the nature of coal slurry. For example, adding foam-breaking agent to coal slurry containing foam, adding dispersant to clay slurry, etc.

Maintain equipment condition

Regular inspection and maintenance of the equipment condition to ensure its normal operation can effectively improve the coal slurry dewatering effect. For example, replace the filter cloth, check the seal, clean the drum shell, etc. on a regular basis.

Improving the operation method

Changing the operation method can improve the coal slurry dewatering effect. For example, shorten the mixing time, appropriately reduce the concentration of added chemicals, etc.

Conclusion

Failure to dry coal slurry pressure is a common problem in the coal washing process, which is mainly caused by the nature of coal slurry, equipment condition and operation problems. By optimizing the nature of coal slurry, maintaining the condition of equipment and improving the operation, the dewatering effect of coal slurry can be effectively improved and the problem of coal slurry not being pressed dry can be avoided.

The main products of flocculant manufacturer Xinhuan Water Treatment are:

White polyaluminium chloride (food grade),

drinking grade polyaluminium chloride,

industrial grade polyaluminium chloride,

anionic polyacrylamide,

cationic polyacrylamide, nonionic polyacrylamide, petroleum recycling polyacrylamide, oil recovery polyacrylamide, polyacrylamide, polymer flocculant polymer flocculation coagulant, polymeric ferrous sulphate, polymerized iron and aluminium chloride, and other water treatment chemicals. Welcome customers to write to us to negotiate business! Tel/WhatsApp:86 15936201203 Email:maggie@xhwtm.com Contact:Maggie

Conclusion

Failure to dry coal slurry pressure is a common problem in the coal washing process, which is mainly caused by the nature of coal slurry, equipment condition and operation problems. By optimizing the nature of coal slurry, maintaining the condition of equipment and improving the operation, the dewatering effect of coal slurry can be effectively improved and the problem of coal slurry not being pressed dry can be avoided.

The main products of flocculant manufacturer Xinhuan Water Treatment are:

White polyaluminium chloride (food grade), drinking grade polyaluminium chloride, industrial grade polyaluminium chloride, anionic polyacrylamide, cationic polyacrylamide, nonionic polyacrylamide, petroleum recycling polyacrylamide, oil recovery polyacrylamide, polyacrylamide, polymer flocculant polymer flocculation coagulant, polymeric ferrous sulphate, polymerized iron and aluminium chloride, and other water treatment chemicals. Welcome customers to write to us to negotiate business! Tel/WhatsApp:86 15936201203 Email:maggie@xhwtm.com Contact:Maggie

Conclusion

Failure to dry coal slurry pressure is a common problem in the coal washing process, which is mainly caused by the nature of coal slurry, equipment condition and operation problems. By optimizing the nature of coal slurry, maintaining the condition of equipment and improving the operation, the dewatering effect of coal slurry can be effectively improved and the problem of coal slurry not being pressed dry can be avoided.

The main products of flocculant manufacturer Xinhuan Water Treatment are:

White polyaluminium chloride (food grade), drinking grade polyaluminium chloride, industrial grade polyaluminium chloride, anionic polyacrylamide, cationic polyacrylamide, nonionic polyacrylamide, petroleum recycling polyacrylamide, oil recovery polyacrylamide, polyacrylamide, polymer flocculant polymer flocculation coagulant, polymeric ferrous sulphate, polymerized iron and aluminium chloride, and other water treatment chemicals. Welcome customers to write to us to negotiate business! Tel/WhatsApp:86 15936201203 Email:maggie@xhwtm.com Contact:Maggie